How Metal Castings support innovation in different industries

Exploring the Versatile Utilizes and Applications of Light Weight Aluminum Castings in Modern Industries

Aluminum spreadings have actually become indispensable to numerous modern-day markets as a result of their one-of-a-kind properties. They offer significant advantages in weight reduction, thermal conductivity, and deterioration resistance. From vehicle advancements to applications in customer goods and building, their adaptability is exceptional. The real extent of their impact expands past immediate benefits, hinting at more comprehensive effects for sustainability and effectiveness. What lies in advance for light weight aluminum castings in an ever-evolving commercial landscape?

Automotive Industry Innovations

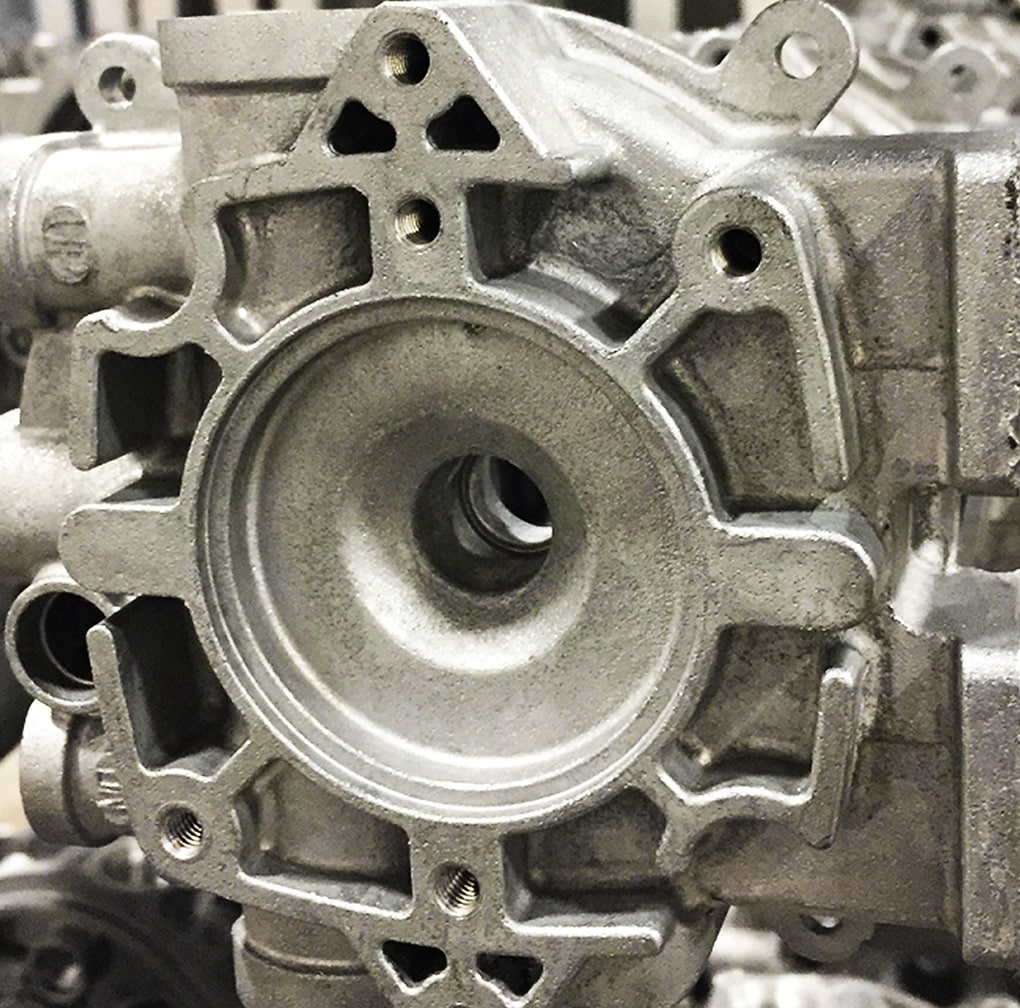

The auto sector has increasingly embraced aluminum spreadings to enhance vehicle efficiency and effectiveness. By utilizing light weight aluminum, producers can produce lighter parts, which add to improved gas economic climate and reduced discharges. Key applications consist of engine blocks, transmission situations, and architectural parts, where the product's strength-to-weight ratio provides resilience without including excess weight.

Aluminum spreadings likewise supply remarkable thermal conductivity, which aids in better warmth dissipation, thus boosting engine performance. In addition, developments in casting modern technologies, such as die casting and sand spreading, enable the production of intricate geometries, enabling cutting-edge designs that enhance space and performance.

The recyclability of light weight aluminum aligns with sustainability goals in the automotive field, promoting ecologically pleasant techniques. As the industry remains to innovate, the usage of aluminum castings is likely to broaden, driving more advancements in car style and efficiency.

Aerospace Applications and Improvements

While the aerospace sector remains to focus on weight decrease and gas efficiency, light weight aluminum spreadings have actually arised as a critical material choice for various applications. Their lightweight nature, paired with high strength-to-weight proportions, enables significant enhancements in aircraft efficiency and effectiveness. Light weight aluminum spreadings are frequently made use of in architectural elements, such as body frameworks and wing components, where lowering weight is important.

Recent developments in aluminum spreading modern technologies, including improved alloy solutions and precision spreading methods, have better improved the material's efficiency abilities. These technologies make it possible for the production of intricate geometries and complex styles while maintaining architectural integrity. Furthermore, aluminum's superb rust resistance guarantees durability and reliability in rough aerospace atmospheres.

As the aerospace field significantly accepts sustainability, aluminum spreadings use a recyclable option that aligns with eco-friendly practices, making them a crucial aspect in the development of next-generation airplane.

Customer Product and Everyday Products

As customers significantly look for lightweight yet durable products for daily items, aluminum spreadings have actually gotten appeal in numerous durable goods. The special residential properties of aluminum, including its resistance to rust and superb thermal conductivity, make it an excellent option for products like cookware, home devices, and exterior gear. For example, aluminum cast pans and pots offer even warm circulation, boosting cooking efficiency. In addition, making use of aluminum in items such as bike structures and travel luggage assures a balance between strength and mobility. Makers value light weight aluminum spreadings for their adaptability, as they can be easily molded into complex shapes while maintaining structural integrity. The ability to reuse aluminum without weakening its buildings aligns with growing consumer choices for lasting products. Overall, aluminum spreadings are essential to the production of durable, useful, and cosmetically pleasing durable goods, meeting the needs of contemporary way of livings.

Building And Construction and Architectural Makes Use Of

Aluminum castings have actually ended up being an important component in building and architectural layout, especially due to their toughness and light-weight nature. These homes make aluminum an optimal choice for numerous applications, including architectural aspects, exteriors, and ornamental features - Aluminum Castings. Engineers and building contractors significantly use light weight aluminum spreadings for window frameworks, doors, and roof systems, improving both functionality and visual appeals. The product's resistance to rust even more extends its life-span, reducing upkeep costs and making certain resilience in varied environmental conditions

In addition, aluminum can be quickly built into complex layouts, allowing for ingenious building expressions. Its flexibility assists in the production of custom pieces that satisfy certain layout demands, from ornate railings to complicated assistances. As sustainability comes to be a top priority, aluminum's recyclability contributes to its appeal in environmentally friendly building practices. Generally, light weight aluminum spreadings are reinventing the building and construction sector by giving light-weight, long lasting, and visually enticing remedies.

Digital and electric Parts

Light weight aluminum castings play an essential role in the production of light-weight electric rooms, which enhance portability and efficiency in numerous applications. Additionally, their superb thermal conductivity makes them excellent for warmth sinks, making certain peak efficiency and long life of digital elements. Additionally, aluminum's conductive homes add to its usage in numerous electrical conductors, emphasizing its importance in modern-day technology.

Light-weight Electrical Units

Light-weight electric enclosures play an essential duty in securing sensitive digital components from ecological elements and physical damage. Constructed from aluminum spreadings, these enclosures are valued for their strength-to-weight proportion, making them optimal for numerous applications throughout sectors. Their light-weight nature aids in minimizing overall system weight, which is vital in mobile and mobile electronic devices. Light weight aluminum's corrosion resistance improves durability, expanding the lifespan of the enclosed parts. The ability to mold light weight aluminum into complicated forms permits personalized layouts, catering to particular needs while ensuring efficient warm dissipation. Additionally, these rooms can be conveniently incorporated into existing systems, offering versatility and convenience in modern technical settings. Generally, lightweight aluminum rooms substantially add to the efficiency of digital devices.

Warm Sinks and Conductors

While lots of products are made use of in digital parts, light weight aluminum castings stand apart for their effectiveness in warm monitoring as warmth sinks and conductors. Their excellent thermal conductivity allows for effective warmth dissipation, which is essential in preventing the overheating of electronic tools. Light weight aluminum's light-weight nature better boosts its viability for applications where weight is a significant element, such as in aerospace and automobile industries. Additionally, aluminum spreadings can be conveniently built right into intricate forms, supplying style flexibility for optimizing thermal performance. The rust resistance of aluminum also contributes to the long life and dependability of these elements in various environments. As technology developments and devices end up being more compact, the need for efficient heat monitoring visit our website options, like light weight aluminum spreadings, continues to grow.

Marine Industry Application

The aquatic market significantly depends on aluminum spreadings for their extraordinary longevity and corrosion resistance. These buildings make light weight aluminum an ideal choice for various applications, consisting of watercraft hulls, engine elements, and marine equipment. The lightweight nature of light weight aluminum castings allows improved gas effectiveness and easier ability to move in watercraft, which is crucial for both leisure and business vessels.

Aluminum spreadings likewise provide substantial price benefits because of their long life-span and reduced maintenance demands, minimizing the overall functional costs for aquatic operators. Additionally, the adaptability of aluminum permits elaborate layouts that can satisfy particular efficiency requirements.

Suppliers in the marine field utilize innovative casting methods to produce intricate shapes, making sure that components satisfy strenuous safety and efficiency standards. As the need for high-performance aquatic vessels grows, light weight aluminum castings are placed as a key material in improving the functionality and durability of aquatic devices.

Sustainability and Recycling in Light Weight Aluminum Casting

Light Weight Aluminum Recycling Process

Reusing light weight aluminum plays a vital duty in decreasing environmental influence and conserving resources within the spreading sector. The aluminum reusing procedure begins with the collection of scrap aluminum, which can consist of old parts, manufacturing waste, and post-consumer products. This scrap is after that arranged, cleaned, and shredded right into small pieces to facilitate melting.

When prepared, the light weight aluminum scrap is thawed in a furnace at lower temperatures than main aluminum manufacturing, greatly decreasing power intake. The liquified light weight aluminum is then cast into ingots or other shapes for reuse in different applications - Aluminum Castings. This closed-loop system enables the effective healing of light weight aluminum, maintaining its properties while decreasing the need for virgin materials. As a result, the reusing procedure is a vital part of lasting techniques in light weight aluminum spreading

Environmental Benefits

While light weight aluminum spreading plays a critical duty in different markets, its environmental benefits are particularly impressive pertaining to sustainability and source preservation. The lightweight nature of aluminum adds to power effectiveness in transportation, reducing fuel intake and discharges. Furthermore, aluminum spreading assists in making use of recycled materials, greatly decreasing the power required for manufacturing contrasted to key light weight aluminum. This reusing process lessens waste and reduces the environmental influence related to mining and refining basic materials. Moreover, light weight aluminum is 100% recyclable without destruction of its properties, advertising a sustainable lifecycle. By selecting light weight aluminum casting, industries can substantially decrease their carbon impact while promoting source efficiency, making it an essential choice in the search of ecologically friendly manufacturing techniques.

Closed-Loop Solutions

Regularly Asked Inquiries

What Are the Secret Benefits of Light Weight Aluminum Castings Over Various Other Products?

Aluminum spreadings supply light-weight homes, Home Page superb corrosion resistance, and high strength-to-weight ratios. They can be quickly formed right into intricate forms, provide good thermal and electrical conductivity, and are affordable, making them more effective over several alternate products.

Exactly how Is the Light Weight Aluminum Spreading Refine Eco Pleasant?

The light weight aluminum spreading procedure is eco-friendly due to its recyclability, low energy consumption, and reduced waste manufacturing. Its capacity to make use of recycled products decreases the carbon impact, advertising sustainability within producing techniques.

What Are Common Challenges in Light Weight Aluminum Spreading Manufacturing?

Usual difficulties in aluminum casting production consist of preserving dimensional accuracy, managing thermal contraction, protecting against defects like porosity and inclusions, ensuring correct mold and mildew layout, and maximizing manufacturing effectiveness while reducing material waste and ecological effect.

How Do Light Weight Aluminum Castings Contrast in Cost With Various Other Manufacturing Methods?

Light weight aluminum spreadings usually provide affordable expenses compared to various other producing methods, especially for medium to high-volume manufacturing. Their lower initial tooling expenditures and efficient product use can result in desirable economics with time.

What Future Trends Are Expected in Light Weight Aluminum Spreading Technology?

Future fads in aluminum spreading innovation are prepared for to include advancements in automation, boosted alloy structures, boosted reusing methods, and the combination of 3D printing, all focused on boosting performance, reducing costs, and decreasing ecological effect.

Current developments in light weight aluminum casting innovations, consisting of improved alloy formulations and precision spreading strategies, have actually even more boosted the product's performance capacities. Aluminum castings have actually come to be a vital part in go now construction and architectural layout, specifically due to their strength and lightweight nature. The light weight aluminum recycling procedure starts with the collection of scrap light weight aluminum, which can consist of old components, manufacturing waste, and post-consumer products. Once prepared, the aluminum scrap is thawed in a heater at reduced temperatures than key light weight aluminum manufacturing, greatly reducing energy intake. In addition, light weight aluminum casting assists in the use of recycled products, substantially decreasing the power needed for manufacturing contrasted to key light weight aluminum.